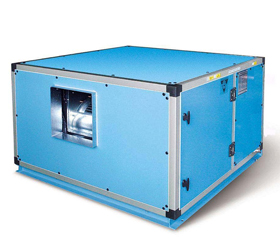

FAN SECTION

RANGE:

- Floor mounted fan section are available from 2000 CFM to 35000 CFM.

- Ceiling suspended fan section are available from 1200 CFM to 4000 CFM (Direct Driven) and 3000 CFM to 6000 CFM (Belt Driven)

- Calculations of cooling loads and air flow requirements for each control zone. Psychrometric analysis for critical areas, calculation of reheat figure, selections of apparatus dew points and finalizing air treatment process.

CASING : (DOUBLE / SINGLE SKIN)

- Rigid corrosion resistant extruded aluminium hollow framework held together with fiber glass corner joints.

- Double skin sand-witched panels with inner skin of 24 G (0.6 mm) plain galvanized steel sheets & outer skin of 24 G (0.6 mm) pre-coated galvanized steel sheet.

- Casing Panels are injected with high pressure PUF insulation having density of 38±2 kg/m³. Standard AHU models have 25 mm thick panel.

- Die cast aluminium hinges and nylon handle on each access door.

- Assembly is done using self drilling and self tapping galvanized sheet metal screws.

- Floor mounted Units are skid mounted. The base frame is rugged in construction made from galvanized steel sheet.

- Ceiling suspended fan section are also available.

- Double skin casing is standard.

- SINGLE SKIN casing in 18 / 16 gauge pre-coated GI sheet is also available as an option.

FAN & MOTOR

- Fans are centrifugal, DIDW forward curved. Fans are energy efficient & AMCA certified. Horizontal fans are belt driven while ceiling suspended fan section have both direct and belt driven models.

- Motors are TEFC, Squirrel Cage Induction type with class ‘F’ insulation confirming to IS 325. Motors are suitable for 3 phase 415±10% V, 50±5% Hz AC supply. Direct driven motors are suitable for single phase 220 V, 50 Hz AC supply. Energy efficient level 1 motor as per IS 12615 can be provided on request.

- Fan & Motor are mounted on common extruded aluminium channel base frame.

- The combined fan motor base frame is mounted on suitable vibration isolator to minimize vibration transmission.

- The fans are connected to the casing through fire resistant canvass.

- Fresh air Fan Section outlet shall have flanged connection for duct connection.

- Exhaust air Fan Section outlet and inlet shall have flanged connection for duct connection.

- Fresh air Fan section shall be provided with pre-filter

- Fan Section can have either of the following air discharge orientation, Up Blast/ Top Horizontal/ Bottom Horizontal.

- Fan Section can also have backward curved fan as an option.

Become a fan

Become a fan  Become a fan

Become a fan