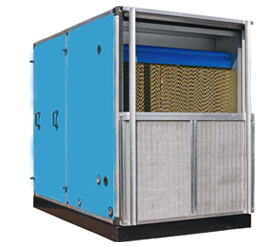

Double / Single Skin Air Washer – Evaporative Cooling

An Evaporative Air Washer Cooling System provides low first and operating cost alternative to refrigerated air conditioning. Air Washer produces effective cooling by combining a natural process of water evaporation with reliable air motion system. Energy is removed from air stream adiabatically.

Direct Evaporative cooling is used to lower the temperature of air using latent heat & evaporation changing of water to vapour. In the process, the energy in the air in the air does not change. Warm dry air is changed to cool moist air. Heat in the air is used to evaporate air. Air cooling is a single pass air system whereby adequate air exhaust arrangement should be planned. Evaporative cooling is suited for dry and hot climate. Also it can used to advantage to ventilate areas of high heat generation.

Applications :

- Industrial Plant

- Commercial Kitchen

- Food Courts & cafeteria

- Laundries

- Warehouses

- Workshops

- Spot Cooling

- DG Ventilation

- Comfort Ventilation

- Poultry Farm, Green house & mushroom farming

Advantages :

- Less expensive to install

- Less expensive to operate, Energy efficient

- Ease of maintenance

CONSTRUCTION FEATURES

Casing

Double Skin casing panels with 25/ 50 mm thick PUF Panel supported on extruded aluminium hollow profile frame work. The inner & outer skins are plain & pre-coated GSS.

Or

Single skin GSS panels on extruded aluminium frame work

Fan & Motor

DIDW, Forward / backward curved AMCA certified centrifugal fan, belt driven complete with TEFC, squirrel cage induction, class ‘F’ insulation, IP-55 motor. Fan motor is suitable for 3 ph, 415 V ± 10%, 50 Hz AC. Fan & motor are mounted on a common base frame on vibration isolator.

Wet Deck

It contains specially treated cellulose paper fill media which is capable of absorbing and retaining water to provide maximum cooling efficiency. This media does not allow water carry over if the face velocity over the media is kept below 2.5 m/sec. Cross corrugation of media maximizes mixing of air & water for attaining higher saturation efficiency. Standard pad thickness is 200 mm.

Water Storage Tank

Heavy gauge galvanized sheet, (MS sheet with FRP Lining optional) complete with make up, overflow & drain connection.

Pump

Monobloc centrifugal pump is provided for water re-circulation.

Pre-filters

Pre-filters are provided to minimize dust loading of paper media. These filters are 50 mm thick. Pre-filters can be either of synthetic non woven media or expanded aluminium mesh

Options

- a. Cooling Pad thickness to meet higher saturation efficiency.

- b. Single bank spray chambers with multi bank PVC eliminators for Scrubbers in place of cooling pad media.

- c. Multi bend PVC eliminator

- d. Standby pump

MODEL NO

AIR QTY

FAN

COIL FACE AREA

MOTOR

OVERALL DIMENSION

CFM

CMH

DIA (mm)

NOS

SQFT

SQMT

KW

H (mm)

W (mm)

L (mm)

UAW 003

3000

5100

280

1

6

0.56

2.2

1100

1000

1700

UAW 005

5000

8500

400

1

10

0.93

3.7

1400

1250

1850

UAW 006

6000

10200

450

1

12

1.11

3.7

1500

1400

1850

UAW 008

8000

13600

500

1

16

1.49

3.7

1600

1550

2000

UAW 010

10000

17000

560

1

20

1.86

5.5

1600

1750

2150

UAW 012

12000

20400

630

1

24

2.23

5.5

1900

1850

2300

UAW 014

14000

23800

710

1

28

2.60

7.5

1900

2000

2350

UAW 016

16000

27200

710

1

32

2.97

7.5

2100

2000

2450

UAW 018

18000

30600

710

1

36

3.34

11

2250

2200

2600

UAW 020

20000

34000

800

1

40

3.72

11

2250

3350

2700

UAW 022

22000

37400

800

1

44

4.09

11

2700

2450

2350

UAW 025

25000

42500

900

1

50

4.65

11

3000

2600

2350

UAW 030

30000

51000

900

1

60

5.57

15

3000

3000

2450

UAW 035

35000

59500

1000

1

70

6.50

15

3000

3100

2450

UAW 040

40000

68000

800

2

80

7.43

11 x 2

2700

4000

2450

UAW 050

50000

85000

900

2

100

9.29

11 x 2

3000

4000

2450

Note :

- a. Pad area indicated is based on 500 FPM (2.5 m/sec) face velocity

- b. Pad thickness considered is 8 inch (200 mm) suitable for 90% saturation efficiency

- c. Motor rating indicated is based on total static pressure of 50 mm WG

- d. Unit Dimensions indicated are approximate only based on “DRAW THRU” arrangement, pre-filter 200 mm thick pad and fansection with 25 mm PUF panels.

- e. Standard models include forward curved, DIDW Centrifugal Fans with single pump

- f. Motors are suitable for 3 Ph, 415 V, 50 Hz, AC

- g. Specifications are subject to change without notice.

Become a fan

Become a fan  Become a fan

Become a fan